Welcome to Viraj Technocast Pvt. Ltd.

Viraj Technocast Pvt. Ltd, established in 2014 is modern Foundry, located at Padavala (Rajkot) in India. Company covers an area of 45000 square feet. Manufacturer of Stainless steel, Alloy steel, Carbon steel, Duplex steel, Nickel base alloys weights up to 900 Kg per piece for Oil and Gas Industry, Earthmoving Equipment, Mining Equipment and other Engineering Industries. The company has planned to produce 1400MT of casting per year.

The company’s day to day affairs and overall management is looked by highly qualified management team. The company has set up facilities to manufacture casting up to 900 kg as a single piece,equipped with all testing machines along with ISO 9001-2008 certification .Castings with a vertical integration to deliver fully machined, proof machine & un-machine components

Industries served

- Valves Industries

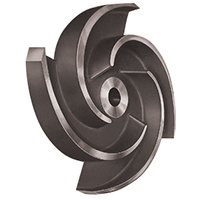

- Pumps Industries

- Automotive Industries

- Power Plant

- Boiler Industries

- Marine

- Defense Castings

- Earth Moving

- Mining Industries

- General Engineering

About Us

The company's day to day affairs and overall management is looked by highly qualified management team. The company has set up facilities to manufacture casting up to 900 kg as a single piece,equipped with all testing machines along with ISO 9001-2008 certification. Castings with a vertical integration to deliver fully machined, proof machine & un-machine components

Industries served

- Valves Industries

- Pumps Industries

- Automotive Industries

- Power Plant

- Boiler Industries

- Marine

- Defense Castings

- Earth Moving

- Mining Industries

- General Engineering

About Us

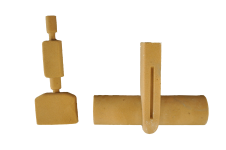

Products

Viraj Technocast Pvt. Ltd, manufacturing high quality steel castings made of carbon steel, stainless steel Duplex steel, Nickel base alloys etc.

Product List:

– Ball Valves Components.

– Gate Valves Components

– Butterfly Valves Components

– Plug Valve Components

– Engineering Components

Specifications/ Grade:

The company follows standards as per customer specifications, major standard followed are:-ASTM, IS, DIN, BS

Products

Viraj Technocast Pvt. Ltd, manufacturing high quality steel castings made of carbon steel, stainless steel Duplex steel, Nickel base alloys etc.

Specifications/ Grade: The company follows standards as per customer specifications, major standard followed are:-ASTM, IS, DIN, BS

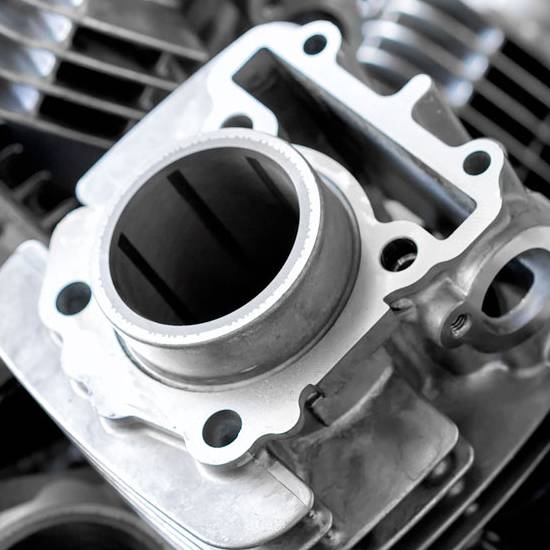

Casting

Forging

Machining

What is Metal Casting?

Metal casting is a modern process with ancient roots. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal casting is arguably the earliest and most influential industrial process in history. It is used to make many of the metal objects used in our daily lives: automotive parts, train wheels, lamp posts, school bus pedals, and much more. Plus, metal casting foundries rely on metal recycling as a cost-efficient source of raw material, significantly reducing wasted scrap metal that might end up in landfills.

The Metal Casting Process

Pattern Making

A pattern is a replica of the exterior of the casting. Patterns are typically made of wood, metal, plastic, or plaster. Patternmaking is incredibly important for industrial part-making, where precise calculations are needed to make pieces fit and work together.

Core Making

If a casting is hollow, an additional piece of sand or metal (called a core) shapes the internal form to make it hollow. Cores are typically strong yet collapsible so they can be easily removed from the finished casting.

Molding and Coating

To visualize the metal casting process so far, imagine yourself walking on the beach toward the ocean. Look at a footprint you leave behind in the wet sand. Your foot would be the core, and the impression left in the sand is a mold of your foot. Molding is a multistep process that will form a cast around the pattern using molding sand. In casting, a mold is contained in a frame called a flask. molding sand, is packed into the flask around the pattern. This is known as metal sand casting. Once the sand is packed tight, the pattern can be removed and the cast will remain. Alternatively, a two-piece, non-destructible metal mold can be created so that the mold can be used repeatedly to cast identical parts for industrial applications.

Melting and Pouring Molten Metal

After metal is melted, it is poured into the cavity of the mold and left to solidify. Once solidified, the shakeout process begins: the molds undergo vibration to remove sand from the casting.

Cleaning

In this final step, the cast metal object is removed from the mold and then fettled. During the fettling, the object is cleaned of any molding material, and rough edges are removed.

Clients

Clients

APPROVED SUPPLIERS

APPROVED SUPPLIERS

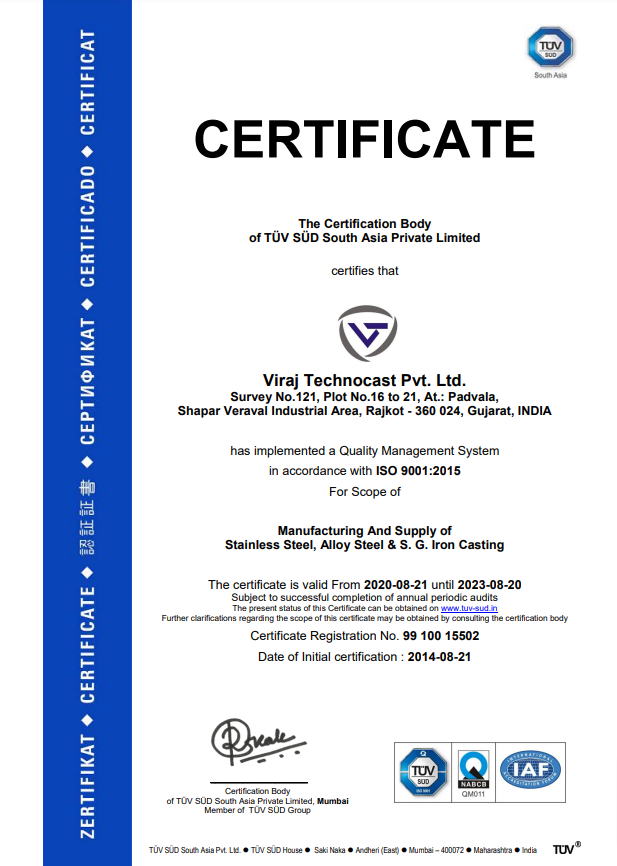

Quality

The quality department of Viraj Technocast Pvt.Ltd is well equipped to requirements at every stage of the manufacturing process.

– 33 Elements spectrometer including Nitrogen analysis is with standard samples for standardization.

– Wet Analysis facility for raw materials.

Sand Testing Laboratory:

With complete range of testing equipment for laboratory work as well as for use on the shop floor, including the equipment for testing Sieve analysis , Permeability, Friability, Moisture content, Compression strength, Penetration strength etc.

We are committed to:

Produce goods with excellent performance and at a competitive price. Continues improvement in our Quality, Environmental and Occupational Health & safety performance through efficient systems and procedures, Viraj Technocast Pvt Ltd shall be committed to supplying goods and services of the highest quality standards, backed by efficient after-sales services consistent with the requirements of the customers to ensure their total satisfaction.

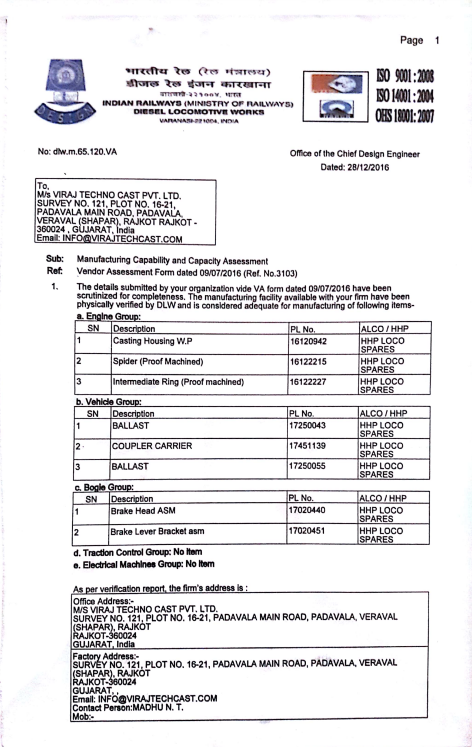

Certifications

ISO 9001:2015 by TUVSUD

Railway Certificate By Indian Railway

AD2000 Merkblatt W0 by TUVSUD

Products Gallery

Viraj Technocast PVT. LTD

Works

Survey No.121. Padavala Village Road, Opp: Waterflo Piping System,

Veraval(Shapar) Industrial Area, Dist-Rajkot – 360 024 (Gujarat)INDIA.

Office

Veraval Main Road, BSNL Telephone Exchange Street,

Nr. Kawa Press Veraval(Shapar) 360024 Dist. Rajkot Tal: Kotdasangani